Ceramic components for medical systems

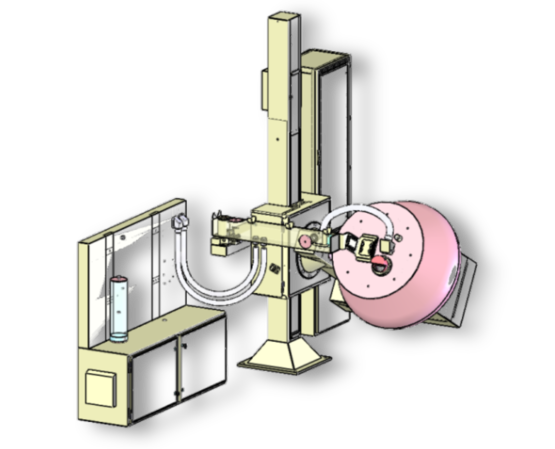

A coating drum mixer with spraying function is an essential part of the production of high-quality ceramic components. The spraying function allows liquids to be applied evenly to the ceramic powder, resulting in a homogeneous mixture. Recipe management allows precise mixing ratios to be stored and recalled, ensuring consistent and high-quality results.

The challenge

The challenge when mixing ceramic powder is to evenly mix batches of ceramic powder with water or oil in order to obtain a mass for subsequent pressing. The pure powder would not stay in shape. The system must allow the operator to distribute a precisely defined quantity of additives into the material, using proven features such as recipe management. There is also the additional requirement that sieving should take place after mixing, which is why the machines have a significantly larger maximum stroke.

Solution and benefit

The machine is specially tailored to the customer's needs and enables standard containers to be picked up and emptied directly into the mixing drum. This applies to both the starting material and the finished mixed product. The machine is supplied including installation and commissioning, which gives the customer the security of being able to start production quickly and maintain the usual quality. In order to meet the high demands of the industry, the design of the machine is adapted to the pharmaceutical environment.

RESULT, Outcome

The increasing global demand for high-tech ceramics, technical ceramics, high-performance ceramics and medical ceramics requires systematic and efficient manufacturing processes. These processes must be able to meet the high quality standards and specific requirements of the various ceramic applications.

A coating drum mixer with spraying function, which is specially tailored to the customer's needs, plays a decisive role in the production of high-quality ceramic components. Precise recipe management and the ability to empty standard containers directly into the mixing drum ensure a uniform and homogeneous mixture. This is particularly important to ensure the consistency and quality of the end products.

The adaptation of the machine to pharmaceutical standards demonstrates how flexible and adaptable these technologies can be to meet the different requirements of the industry. The combination of advanced technology and customized solutions makes it possible to efficiently meet the increasing demand for high-quality ceramic products.