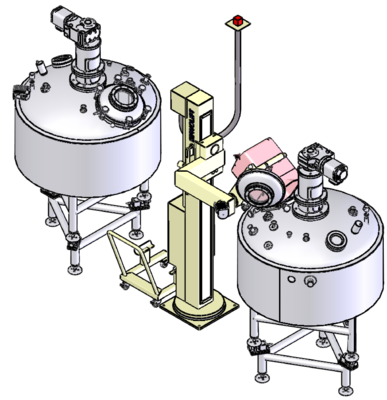

Intelligent supply of blood plasma in reactors

A reliable system for handling frozen blood plasma was the customer's most important requirement. It must be ensured that there are no losses of this precious product. Therefore, a new automated feeding system was installed, which largely eliminates errors through additional safety devices. Octapharma's project manager is very satisfied with the result and found Servolift to be a trustworthy partner.

CHALLENGE

Automation and safety: One of the biggest challenges was to change a manual process into a fully automated one while ensuring the safety of the operators. The automatic feed had to function safely without operator intervention.

Space restrictions: The highly confined space layout made it difficult to install the automation system, which required innovative solutions.

Quality and reliability: Handling the precious plasma required precise handling to prevent malfunctions and, in the worst case, losses. The reliable functioning of the system was therefore of crucial importance.

Tight shedule: The project had a tight timeframe of a maximum of three weeks for the mechanical and electronic adjustments and test runs, leaving little room for maneuver during implementation.

Solution and benefit

The long-term benefits of automating the lifting system at Octapharma are considerable:

Incrased productivity: automation relieves operators from manually controlling the system. This allows operators to focus on other important tasks, which ultimately has a positive impact on overall productivity.

Greater safety: The automated system, monitored by safety scanners and augmented PLC, significantly reduces the risk of accidents and injuries. This creates a safe working environment for operators, even in confined spaces.

Consistency and reliability: Automatic systems are decoupled from human intervention and therefore potential errors, ensuring that the plasma is accurately and consistently fed into the reactors. This reliability is critical given the high value of the plasma.

Cost savings: In the long term, reducing manual labor and minimizing errors can result in significant cost savings. In addition, the automated system can operate continuously without interruption, further increasing efficiency.

In the long term, automation, streamlining the process and minimizing errors will lead to significant cost savings.

Employee satisfaction: Operator satisfaction has increased as they are no longer limited to monotonous operation of the system. By taking on more meaningful tasks, the focus on responsibility and identification has improved.

Scalability: The automation can be scaled for future projects. This provides a basis for further adjustments and improvements to the entire production process.

Overall, the automation of the lifting system is a strategic investment that promises greater efficiency, safety and satisfaction in the long term.

RESULT, Outcome

Automation: The lifting system has been successfully automated so that the operators no longer have to control the equipment manually in 8-hour shifts. This allows operators to focus on more important tasks.

Safety: The implementation of safety scanners and a PLC led to the creation of a safer working environment for the operators, as the system automatically detects people entering the safety zone and stops the system immediately.

Efficiency: The automated system improved efficiency by controlling the supply of plasma into tanks without human intervention.

Reliability: Due to extensive testing and adjustments on site, the system now operates smoothly and meets the high standards that allow no compromise for plasma handling.

Operator satisfaction: Operators are now happier with their work as they are no longer constrained by the manual control of the system and can move on to more important tasks.

Overall, the project has achieved its objectives in terms of automation, safety and reliability, resulting in greater efficiency and operator satisfaction.

Servolift is a partner that is not too far away from our location. That makes collaboration easier. They know our premises and our expectations in terms of hygiene and the design of the machines.

We process blood plasma, a very precious human product, we cannot ethically afford to waste it. There is great value in every batch. It must therefore be ensured that the system functions perfectly from the very first batch. We work with a frozen material. Every minute, every hour that passes can mean the loss of a batch. So there is a lot at stake and we needed a reliable partner.

There are suppliers who promise everything from the outset: “Yes, we can do this, we can do that, and then when it comes to implementation, you realize that it simply can't be done.

Not so with Servolift. I found the openness and the positioning very good when it came to what is feasible and what is not, so that was really positive.